Copyright P T Reid @ Green Equipment Ltd 2021

Registered In England No: 4759703

VAT Number: 824777106

For further information,

Please contact

Pete Reid

www.green-equipment.co.uk

Solvent Recycling Principles

There are three general types of solvent recovery unit.

Simple dry distillation, fractional distillation and thin film evaporation.

During the distillation process, solvents contaminated with pigments, resins, polymers, paints, oils, etc...

are heated in a chamber (distillation column) by electric heaters, steam or thermal oil.

When the solvent has reached it's boiling point (this varies with different solvents), vapour is produced

that is then condensed through a chilled water condenser.

The vapour is condensed back into a liquid as it passes through the condenser and collected in a storage container.

The residues remaining in the distillation column are drained and disposed of as a waste residue.

Distillation units can be batch or continuous operation with automatic feeding of contaminated

solvent and draining of waste residue.

They can be used with vacuum assistance when high boiling point solvents are processed or solvents

containing heat sensitive chemicals such as Nitrocellulose used in printing inks.

Distillation is defined as a process in which a liquid

mixture of two or more substances is separated into

it's component fractions of desired purity, by the

application and removal of heat.

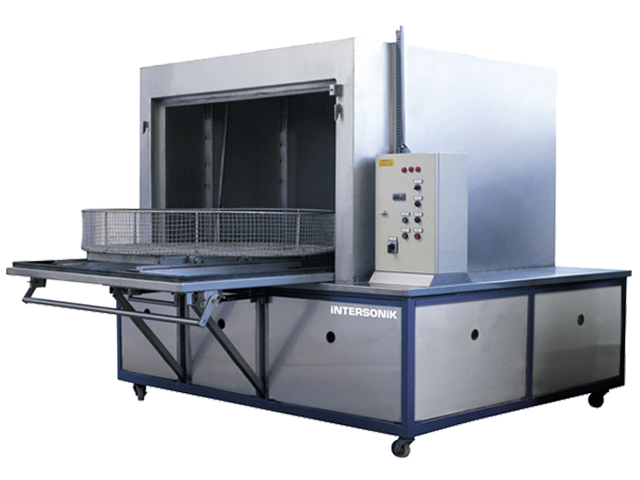

Industrial Cleaning Machines

Washing and cleaning systems can either use solvents or aqueous based solutions depending on what is being cleaned. In either case,

dirty solvents or water can be recycled and used again when recycled with an in-line recovery unit.

There are different principles involved such as immersion, high pressure spray with or without brushing, vapour degreasing etc...

Various cycles of washing are available to suit components being cleaned. This can include pre-wash, wash, pre-rinse, rinse and drying

followed by recovery of washing medium.

Washing machines can vary in size and have different loading capabilities such as

top loading, side loading, end loading, conveyor, tunnel, robotic.

The main advantages of automatic machine washing compared to manual hand cleaning would be:

Reduced operator contact with chemicals

No open tanks of flammable solvents

Using less cleaning chemicals

Less manual labour

Consistently cleaner parts

Reduced downtime of production equipment

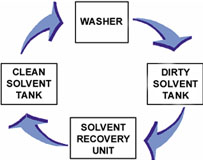

When using washing machines with in-line recycling

units, dirty solvent and waste water can be recycled

to be used again.

Solvent Recycling - Industrial Parts Cleaning - Electrical Testing - Sales - Service

Green Equipment Ltd

01244 374205 or 07939 056170

" We Work With You "